Une articulation à double rotule est un assemblage mécanique très simple. Des billes filetées sont prises en sandwich entre deux plaques et la pression est ajustée à l’aide d’une vis. Des tiges viennent se visser dans les billes que l’on peut orienter et freiner plus ou moins fermement. Elles sont habituellement fabriquées en acier et sont beaucoup utilisées dans le milieu de l’animation.

La version Phluux

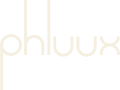

Comme j’aime bien réinventer la roue, j’ai cherché comment en fabriquer sans utiliser d’acier. Une solution sympathique – qui demande d’imprimer une pièce en 3D – est de créer une coupelle qui sert d’intermédiaire entre les plaques et les billes. Cette coupelle augmente la surface de contact par rapport à un simple chanfrein et la souplesse du PLA* permet d’absorber les irrégularités. Cette solution laisse donc plus de choix dans les matériaux utilisés pour les billes ou les plaques.

Le bois est la matière avec laquelle je travaille le plus volontiers. Il est facile d’en récupérer de petites quantités dans les chutes des ateliers et c’est donc ce que j’ai choisi pour les plaques. Ces dernières doivent être suffisamment rigides pour résister à la force de serrage.

Comme billes filetées, j’ai trouvé des boutons de tiroirs dans ma quincaillerie préférée. Le résultat est une articulation légère qui convient parfaitement à l’orientation de petits projecteurs.

Cette articulation est celle que j’utilise dans le projecteur « Nomad » et a été éprouvée par des comédiens dans différentes situations où il est nécessaire de rapidement réorienter un projecteur. Bien sûr, elle est moins adaptée à une installation qui demande un blocage résistant ou permanent.

J’ai jusque là utilisé des molettes de serrage de qualité car l’utilisation de l’articulation en jeu par les comédiens méritait ce type de confort mais dans d’autres situations, un simple écrou suffit et coûte beaucoup moins cher. C’est tout l’intérêt du DIY: on peut toujours adapter un design à nos besoins.

Prenez soins de vos articulations

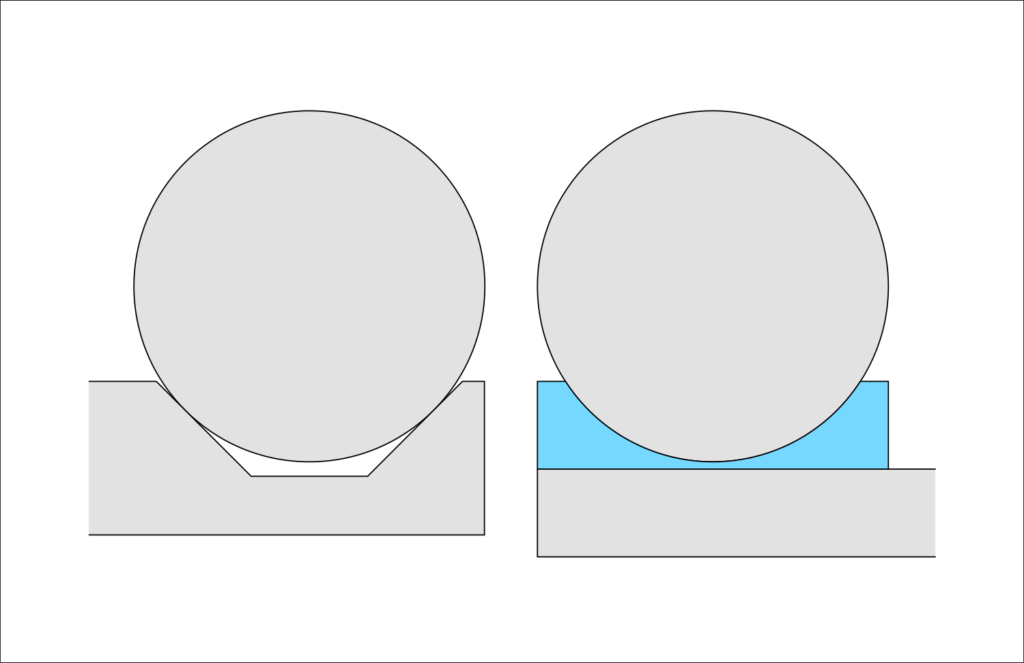

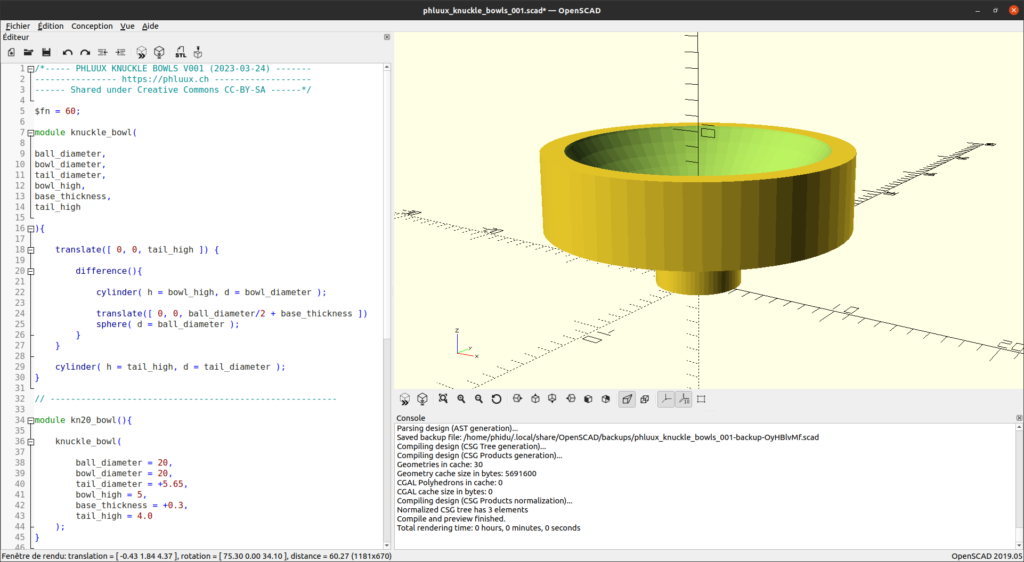

J’ai promis dans de précédents articles que je documenterai mon travail et partagerai mes designs. Ce modèle se prête bien à l’exercice car il est très simple à dessiner et le fichier ** Openscad avec lequel on peut paramétrer de nouvelles coupelles est très court.

Contenu du dossier:

- Un PDF avec les mesures et des références matérielles

- Les STL des deux formats de coupelles (16 et 20 mm).

- Le script Openscad pour en paramétrer de nouvelles

- Les DXF des plaques pour une découpe à la CNC.

- Les SVG des plaques pour exporter vos propres DXF.

Le tout est mis à disposition sous licence CC-BY-SA.

* Le PLA (acide polylactique) est la matière la plus couramment utilisée pour l'impresion 3D ** Openscad est le logiciel que j'utilise pour modéliser les pièces destinées à l'impression 3D.